Model No.︰ULZ-1600+255/15

Brand Name︰Bochuang

Country of Origin︰China

Unit Price︰US $ 350000 / set

Minimum Order︰1 set

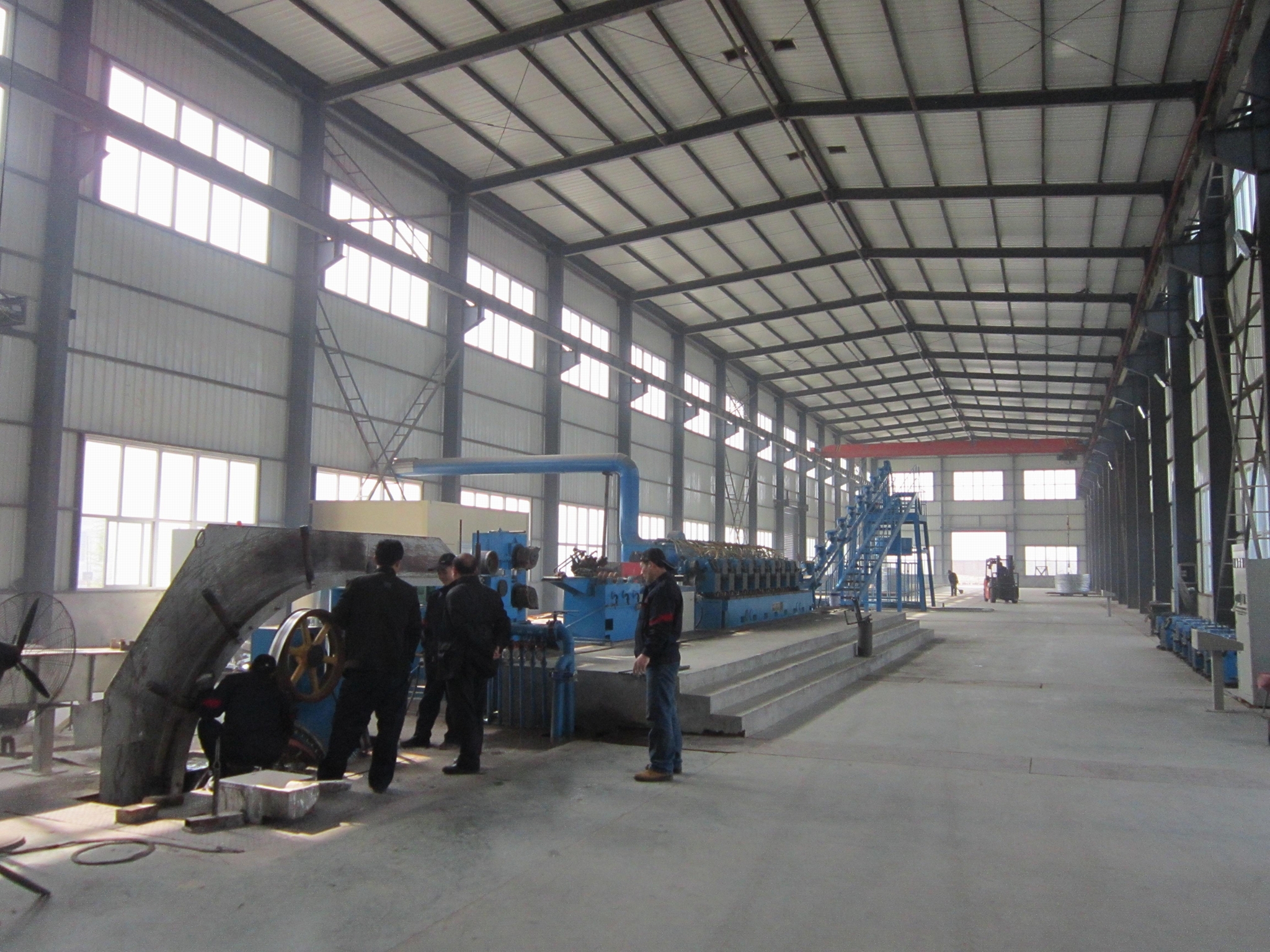

This production line works to produce pure aluminum rod or alloy aluminum rod in diameter of φ9.5mm or φ12mm by means of continuous casting and rolling.

This production line is composed of 5T/H vertical high energy-saving melting furnac, Round Tilting Holding Furnace(2х10T, electromagnetic blender to support the 10T Round Tilting Holding Furnace), in-line degassing & filtering system, 4-wheel casting machine and pouring ladle, roller shears, motorized straightener, multi-frequency induction heater, cast bar feed-in device, rolling mill, alloy rod cooling systems, dual-position coiler, electrical control system, rolling mill lubrication system and emulsion sy.Diameter of casting wheel: φ1600 mm

4.2. Cast bar delivery speed: 8~12mpm

4.3. Cross sectional area of cast bar: 2400mm2

4.4. Motor of casting machine: 4kW (AC, frequency speed regulation)

4.5. Motor of rolling mill: 355kw, 600rpm

4.6. Final rolling speed: 4~6.2m/sec.

4.7. Output: approx. 2.7~4.2 t/h

4.8. Outlet rod diameter: φ9.5mm, Φ12mm, Φ15mm

4.9. Number of stands: 15 (7 stands with Y-shaped rolls of upper driving, 8 stands with Y-shaped rolls of lower driving)

4.10. Pass system: arc triangle – circle

4.11. Nominal diameter of roll: Φ255mm

4.12. Diameter of coil: Φ2000mm

4.13. Weight of coil: approx. 1~1.5 tons/basket

4.14. Total installed power: 950kwstem, etc.